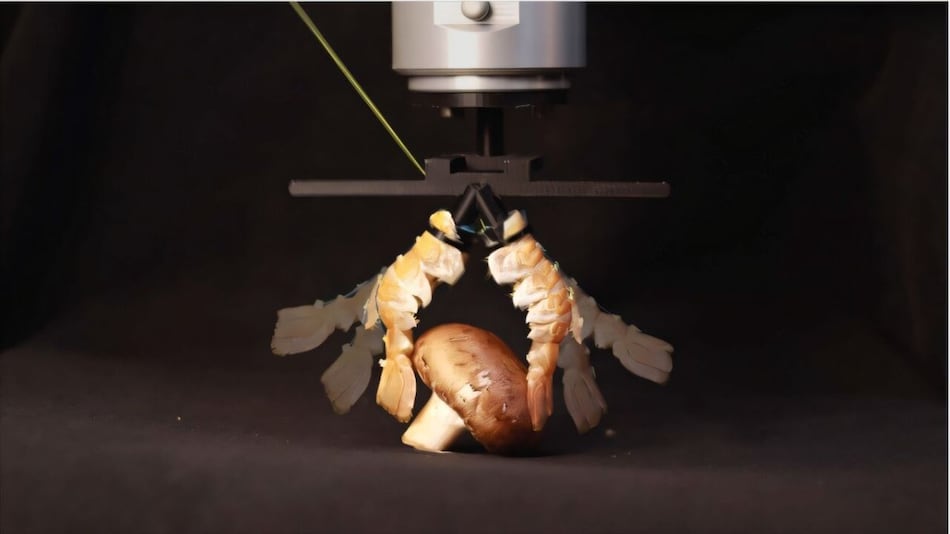

Engineers have repurposed discarded lobster shells into biohybrid robotic parts, creating strong grippers and swimming fins.

Engineers turn shell waste into biohybrid robot grippers and fins, showing food scraps can fuel greener

Click Here to Add Gadgets360 As A Trusted Source

Biohybrid robots combine one hand biology with the other engineering. A single instance is that of joints for robots made out of the leftover shells of crustaceans. These external skeletons are able to move since they are a combination of both rigid and flexible. The team of engineers made the shells soft by impregnating them with polymers and then fixed the motors, thus, they created grippers which are capable of lifting heavy objects and fins which can swim by flapping. The term ‘dead matter’ associated with this design is an indication of how the world’s food waste can be a source of eco-friendly robots.

Designing with Crustacean Shells

According to the paper, EPFL engineers turned lobsters’ discarded tail segments into robotic parts. Each crustacean shell has hard plates linked by flexible membranes, a mix of strength and flexibility. They inserted a soft elastomer into the segments, attached motors, and coated the shell in silicone for durability. In tests, one shell lifted ~500 g and two shells together grasped items from pens to tomatoes; they even served as flapping fins propelling a small robot at about 11 cm/s.

Benefits and Challenges

An eco-friendly twist is added by using waste shells, which allow the robot’s synthetic components to be separated and reused, emulating a circular design. This is presented by the team as a robotics proof-of-concept for recycling food waste. However, difficulties still exist.

Two gripper “fingers” made of different tails bend unevenly because every shell is different, making control more difficult. Because of these peculiarities, bio-hybrid robots require further development before they can be used in the real world.